UHMWPE: Lightweight & Abrasion Resistant

Key Features of UHMWPE:

- Excellent strength to weight ratio

- High abrasion resistance

- Low specific gravity

- UV stable

- Chemically inert except for strong oxidizing acids

- Resistant to fatigue & internal friction

History

Ultra-High Molecular Weight Polyethylene (UHMWPE) was first polymerized in the 1950’s. The first Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers were commercialized in the late 1970’s.

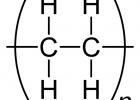

Composition

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyolefin that is composed of very long chains of polyethylene with a very high % of parallel orientation and high level of crystallinity.

The extremely long polymer chains enable load transfer by strengthening intermolecular interactions. UHMWPE fibers are manufactured in a gel spinning process.

FIBER-LINE® Enhancing Processes for UHMWPE:

FIBER-LINE® UHMWPE Products:

Manufacturers

Avient™

Honeywell™

Other suppliers

Common Types & Deniers

Spectra: S900, S1000

Dyneema: SK62, SK65, SK75

Deniers: 50 - 5400

UHMWPE Bare Fiber Performance

UHMWPE Data

Standard Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 28.0 |

| Specific Gravity | Ratio | 0.97 |

| Elongation @ Break | % | 3.6 |

| Tensile Modules | g/d | 850 |

| Moisture Regain* | % | <0.1 |

| Creep** | % | 1.7 - 5.0 |

| Shrinkage*** | % | Melts |

| Melt Point | ℃ | 135 |

High Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 38.0 |

| Specific Gravity | Ratio | .97 |

| Elongation @ Break | % | 3.1 |

| Tensile Modules | g/d | 1250 |

| Moisture Regain* | % | <0.1 |

| Creep** | % | 1.7 - 5.0 |

| Skrinkage*** | % | Melts |

| Melt Point | ℃ | 135 |

* Equilibrium moisture regain @ 55% RH ** Creep @ 40%-58% ultimate tensile strength *** Shrinkage in dry air @ 177 C for 30 minutes

This data is provided for informational purposes only, and does not constitute a specification. FIBER-LINE makes no warranty, express or implied, that the product conforms to these values. Contact your FIBER-LINE representative for exact product details which conform to your specific requirements.