Kevlar® Para-Aramid: Lightweight, Durable, and Strong

Key Features of Kevlar®

- High strength to weight ratio

- Low elongation to break

- Good heat & flame resistance

- Good chemical resistance

- High cut resistance

- Excellent ballistic properties

History

Kevlar® was first developed by chemist Stephanie Kwolek at DuPont™ in the 1930's. It was first commercially used in the 1970’s as a replacement for steel in racing tires.

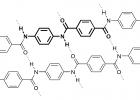

Composition

Kevlar® Para-Aramid is an aromatic polyamide that is characterized by long rigid crystalline polymer chains. “Para” refers to the specific linkage position of the aromatic rings. Longitudinal alignment of the hydrogen bonds enables high tensile strength and modulus.

FIBER-LINE® Enhancing Processes for Kevlar®:

FIBER-LINE® Kevlar® Products:

Manufacturer

DuPont™

Common Types & Deniers

- Kevlar® 29: 200, 400, 1000, 1500, 2250, & 3000 denier

- Kevlar® 100: 1500 denier – Black color

- Kevlar® 49: 380, 1420, 2160, & 2840 denier

- Kevlar® 49 roving: 7100 denier

Kevlar® Para-Aramid Bare Fiber Performance

CHEMICAL COMPATIBILITY

Chemical Resistance to Acid: Degrades in Formic, Hydrochloric and Sodium Hydroxide acid.

Chemical Resistance to Alkali: Strong alkalis will attack at high temperateure or concentration.

Chemical Resistance to Organic Solvent: Degrades moderately in Carbon Tetrachloride and Ethylene Glycol/Water.

Kevlar® Para-Aramid Data

Standard Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 23.0 |

| Specific Gravity | Ratio | 1.44 |

| Elongation @ Break | % | 3.5 |

| Tensile Modules | g/d | 555 |

| Moisture Regain* | % | 5.0 |

| Creep** | % | <0.03 |

| Shrinkage*** | % | <0.02 |

| Melt Point | ℃ | None |

| Decomposition Temp. | ℃ | 425-480 |

High Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 23.6 |

| Specific Gravity | Ratio | 1.44 |

| Elongation @ Break | % | 2.5 |

| Tensile Modules | g/d | 885 |

| Moisture Regain* | % | 5.0 |

| Creep** | % | <0.03 |

| Skrinkage*** | % | <0.02 |

| Melt Point | ℃ | None |

| Decomposition Temp. | ℃ | 425-480 |

* Equilibrium moisture regain @ 55% RH ** Creep @ 40%-58% ultimate tensile strength *** Shrinkage in dry air @ 177 C for 30 minutes

This data is provided for informational purposes only, and does not constitute a specification. FIBER-LINE makes no warranty, express or implied, that the product conforms to these values. Contact your FIBER-LINE representative for exact product details which conform to your specific requirements.